Quadcopters, also known as multirotor drones, have revolutionized industries such as aerial photography, surveying, mapping, delivery services, and surveillance. However, their biggest limitation remains short flight time, typically capped at 20–30 minutes for consumer models and 40–60 minutes for professional drones.

The demand for extended flight time has never been greater. To address this, researchers and manufacturers are focusing on battery technologies for extended drone flight time. Advancements in solid-state batteries for drones, lithium-sulfur systems, and intelligent flight path algorithms are paving the way for drones capable of flying significantly longer, safer, and more efficiently.

This article explores recent battery advancements, compares emerging technologies, reviews real-world applications, and examines the future of drone endurance.

Battery technologies for extended drone flight time Technical Information

Recent Battery Advancements

Lithium-Ion Batteries (Li-Ion)

The most widely used battery type in drones today. Advances in high-nickel cathodes and silicon anodes since 2020 have improved capacity and cycle life.

- Pros: Mature manufacturing, moderate cost, reliable performance.

- Cons: Safety risks at high loads, limited energy density (~250 Wh/kg).

Lithium-Polymer Batteries (Li-Po)

A variant of lithium-ion, Li-Po batteries use polymer electrolytes and provide high discharge rates — essential for drones needing rapid bursts of power.

- Pros: High power output, flexible form factors.

- Cons: Lower cycle life, prone to swelling, requires strict charging protocols.

Solid-State Batteries

One of the most promising latest battery advancements. These replace flammable liquid electrolytes with solid materials, improving both safety and energy density (~350–500 Wh/kg).

- Pros: Non-flammable, longer lifespan, higher energy density.

- Cons: Expensive, still in early commercial deployment.

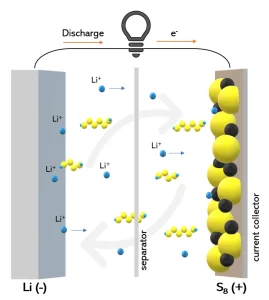

Lithium-Sulfur Batteries (Li-S)

Emerging as a lightweight, eco-friendly alternative with energy densities up to 600 Wh/kg.

- Pros: Extremely lightweight, abundant raw materials, potential to double endurance.

- Cons: Short cycle life (~200–400 cycles), degradation due to polysulfide shuttle effect.

Drone energy-efficient battery solution Optimization Techniques

-

Efficient Flight Algorithms

- AI-powered route planning reduces unnecessary maneuvers.

- Adaptive thrust control balances power consumption based on payload.

-

Weight Reduction Methods

- Carbon-fiber frames, miniaturized electronics, and modular payload designs reduce structural mass by 10–20%.

-

Energy Harvesting Technologies

- Solar-assisted quadcopters: Panels integrated into frames extend flight times by supplementing onboard power.

- Piezoelectric systems: Harvest vibrations into small amounts of usable energy.

-

Motor & Propeller Efficiency

- Brushless DC motors with optimized blade pitch reduce drag and extend flight endurance.

Comparison Table of Battery Technologies for Long-Endurance Drones

Battery Type |

Energy Density (Wh/kg) |

Weight |

Charge Time |

Cycle Life |

Cost |

Applications |

|

Lithium-Ion |

180–250 |

Medium |

60–90 min |

300–500 |

$$ |

Consumer drones, hobby use |

|

Lithium-Polymer |

150–220 |

Light |

45–60 min |

200–400 |

$$ |

Racing drones, FPV |

|

Advanced Li-Ion (High-Ni/Si) |

250–350 |

Medium |

60–90 min |

500–800 |

$$$ |

Professional drones |

|

Solid-State |

350–500 |

Medium-Heavy |

90–120 min |

800–1000+ |

$$$$ |

Industrial UAVs, defense |

|

Lithium-Sulfur |

400–600 |

Very Light |

90–120 min |

200–400 |

$$$ |

Long-range UAVs, research |

|

Hybrid (Li-Ion + Solar) |

~200–250 (+solar assist) |

Heavy |

90–120 min |

400–600 |

$$$ |

Endurance drones |

Case Studies and Real-World Applications of batteries for long-endurance drones

DJI Matrice 300 RTK (Li-Ion Advanced)

- Uses high-density Li-Ion packs with optimized power management.

- Achieves up to 55 minutes of flight time, widely used in surveying and public safety.

SolarXOne (Hybrid Solar + Li-Ion)

- French-developed drone integrating solar panels into wings.

- Extended endurance beyond 12 hours in test flights.

Research Quadcopters with Li-S Batteries

- University-led projects since 2022 have demonstrated 40–60% longer endurance using lithium-sulfur prototypes compared to Li-Po packs.

- Applied in environmental monitoring missions.

Future Drone Batteries: Silicon-Anode Meets Solid-State

The next 5–7 years could see a new class of drone batteries that combine silicon-anode technology with solid-state electrolytes, solving many of today’s limitations.

electrolytes, unlocking a new era of high-energy, lightweight, and ultra-safe power systems.

Silicon anodes offer up to 10× higher capacity than traditional graphite, while solid-state designs eliminate liquid electrolytes, improving safety, thermal stability, and cycle life.

Combined, these technologies could deliver unprecedented endurance and rapid charging—the foundation of the ultimate long-range drone battery.

-

Higher Energy Density (500–600 Wh/kg)

- Solid-state electrolytes allow the use of pure silicon anodes without as much risk of cracking or swelling.

- This could potentially double flight time compared to current Li-ion packs.

- Long-range surveillance drones and delivery UAVs could fly for 2+ hours on a single charge.

-

Improved Cycle Life & Stability

- Solid-state designs prevent dendrite growth (a common issue in Li-ion) and stabilize silicon expansion.

- Expected cycle life: 800–1,200 cycles, making them far more practical for commercial fleets.

-

Enhanced Safety

- Solid electrolytes are non-flammable, reducing the risk of thermal runaway.

- This is critical for drones operating over cities, industrial sites, or sensitive areas.

-

Fast Charging & High-Power Delivery

- Silicon anodes already support rapid charging.

- Pairing with solid-state electrolytes could enable sub-30 minute recharge times, vital for logistics drones.

-

Scalability & Cost Trends

- Early adoption will be in defense and aerospace drones, where performance outweighs cost.

- By 2030, mass production could lower costs enough for prosumer drones (aerial photography, mapping).

Combining silicon-anode and solid-state technology offers one of the most promising routes to significantly extend drone flight times. Although still in the early stages of development, this breakthrough has the potential to transform UAV endurance, safety, and efficiency by the early 2030s.

🔋 Best Drone Batteries Compared: Li-Ion, Li-Po & Silicon-Anode

A clear comparison table showing how silicon-anode lithium-ion batteries stack up against traditional graphite-anode Li-ion and Li-Polymer (Li-Po) batteries in the context of drones:

|

Feature / Battery Type |

Silicon-Anode Li-Ion |

Graphite-Anode Li-Ion |

Lithium-Polymer (Li-Po) |

|

Energy Density (Wh/kg) |

350–450 (higher endurance) |

200–250 (moderate) |

150–220 (lower, but high-power output) |

|

Weight Efficiency |

Excellent – fewer cells needed |

Good, standard |

Good, lightweight form factors |

|

Cycle Life |

200–500 (currently limited) |

300–500 (stable, proven) |

200–400 (lower, especially at high loads) |

|

Charge Speed |

Fast (supports rapid charging) |

Moderate |

Fast (high discharge/charge rates) |

|

Thermal Management |

Needs better cooling (heat buildup) |

Stable under load |

Can overheat if pushed beyond limits |

|

Cost |

$$$ (expensive, emerging tech) |

$$ (affordable, widely available) |

$$ (affordable, very common) |

|

Suitability for Drones |

Best for professional/industrial UAVs needing long endurance |

Reliable choice for consumer drones |

Ideal for racing/FPV drones requiring bursts of power |

Silicon anode lithium-ion batteries are being explored as a promising upgrade for drones. They replace the conventional graphite anode with silicon (or silicon–graphite composites), which significantly increases energy storage. However, they also come with trade-offs that matter in drone applications.

✅ Pros of Silicon Anode Li-ion Batteries for Drones

-

Higher Energy Density

- Silicon can store ~10× more lithium than graphite, pushing energy density to 350–450 Wh/kg.

- For drones, this means longer flight times without adding much weight.

-

Faster Charging

- Enhanced lithium diffusion allows quicker charging — important for commercial drones with tight deployment schedules.

-

Lightweight Advantage

- Higher capacity per cell means fewer cells are needed, reducing total payload weight.

-

Compatibility with Existing Li-ion Systems

- Can often be integrated into existing drone power systems with minimal design changes.

⚠️ Cons of Silicon Anode Li-ion Batteries for Drones

-

Volume Expansion Issues

- Silicon expands by up to 300% during charge/discharge cycles, leading to cracking and shorter lifespan.

- This can be problematic for drones that require consistent reliability over hundreds of cycles.

-

Cycle Life Limitations

- Currently, many silicon anode cells degrade faster than advanced graphite or Li-poly cells.

- Reduced cycle life means more frequent replacements, increasing costs.

-

Thermal Management Challenges

- High-energy density cells generate more heat under load.

- Drones need good cooling systems to avoid performance drops or safety risks.

-

Cost and Availability

- Still more expensive than conventional Li-ion.

- Large-scale, drone-specific production is limited.

Silicon-anode Li-ion is a step toward the next generation of drone batteries, but until cycle stability improves, it may see more use in industrial UAVs before becoming mainstream for everyday consumer drones. They are particularly suitable for high-performance or professional drones where longer endurance is essential, such as aerial mapping, delivery, or surveillance, but remain less practical for budget or hobby drones due to their higher cost and shorter cycle life at present.

Next-Gen Batteries Challenges and Future Trends

Challenges

- Battery Degradation: Even advanced chemistries like Li-S degrade quickly under heavy cycles.

- Safety Risks: Overheating and thermal runaway remain concerns, especially in high-load drones.

- Cost & Scalability: Solid-state batteries are expensive and not yet mass-produced for consumer drones.

- Weight Trade-offs: Adding energy capacity often means heavier packs, reducing net efficiency.

Future Trends

- Nanomaterial Cathodes: Graphene and silicon-based electrodes to push Li-Ion beyond 400 Wh/kg.

- AI-Driven Energy Optimization: Predictive power allocation across motors and payload systems.

- Hybrid Energy Systems: Combining batteries with supercapacitors or solar harvesting.

- Commercialization of Solid-State: Expected between 2025–2027 for high-end drones.

|

Note: These are the 2 main reasons why silicon-carbon batteries are not yet widely adopted While it is one of the Next-Gen Batteries.

|

Conclusion

Energy optimization and battery technologies for extended quadcopters flight time are evolving rapidly. Advances in solid-state batteries for drones, lithium-sulfur chemistry, and AI-based flight algorithms are already demonstrating significant performance gains.

As industries demand longer, safer, and more efficient drone operations, the convergence of battery technologies for extended drone flight time and advanced energy optimization techniques will define the future of quadcopters. For businesses, hobbyists, and researchers alike, staying informed about the latest drone battery innovations ensures smarter choices, improved endurance, and better overall performance.

References

- IEEE Robotics & Automation Letters, 2022. Hybrid Li-S Power Systems for UAV Endurance.

- Nature Energy, 2023. Advances in Solid-State Electrolytes for Next-Gen Batteries.

- ArXiv Preprint, 2024. AI-Based Flight Energy Management for UAVs.

- DJI Official Website, 2024. Matrice 300 RTK Specifications.

- SolarXOne Project, 2023. Solar Drone Endurance Tests.

Further Reading:

- Comparative Analysis of New Aerospace Microcontrollers (2025–2026)

- Edge Vision with ESP32-CAM: Running TinyML Models to Detect Motion, Faces, and Shapes

Siqma is a kind assistant, helping you to have the tools and facilities by your hand, in order to feed your ideas! For years, we have been working hard to satisfy our customers by developing Siqma as platform to make electronic and robotic components easier to access than ever.